After years of technical research and development, our company officially launched grille anti-wear technology to the market in 2014, and registered the national trademark "金梁" brand for this purpose. Around the jinliang grille anti-wear technology, so far has applied for a total of 10 national patents.

Thermal conductivity grille anti-wear technology:

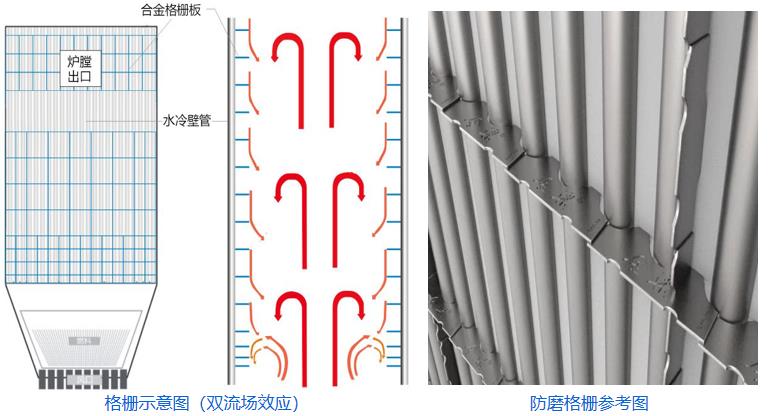

Heat conduction type grille wear technology is in the water wall surface along the horizontal direction and vertical direction, furnish alloy form grid grille grille plate, the formation of the blocking high speed stick wall flow, optimizing water wall surface flow field, eliminate local vortex flow, reduce the gas-solid two phase flow stick wall motion speed, reduce the material particles on the water wall of the cutting force, so as to effectively control the water wall wear problem of a kind of active wear technology.

Grille Anti-wear Theory Picture The Real Picture Seen

According to the operation rules and data obtained from the study, the wear analysis of water-wall tube wear formula is as follows:

Among them, the

T --wear, g / ㎡; μ -- material concentration,g/m3;

W -- material flow rate,m/s; T -- time,h;

K -- wear coefficient; N -- material impact rate;

C--material wear coefficient (closely related to material composition);

Conclusion:

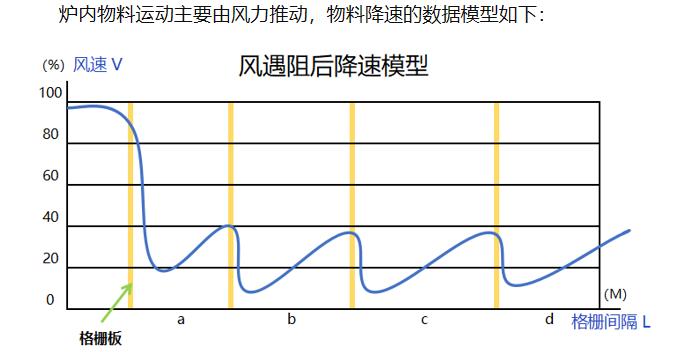

According to the wear formula, the main variable of boiler wear is material velocity. Therefore, if the material velocity on the surface of the water wall can be effectively restrained, the problem of wear on the surface of the water wall can certainly be effectively contained.

Anti-wear principle of 'jinliang' grille anti-wear technology:

Theory:

When wind is blocked, the velocity can be reduced to 20 percent or less. According to the wear formula, the wear rate of the water wall can be reduced to 3.6‰ of the original.

Theoretically, under the same working condition, the maximum life of the water-wall tube can be extended by 277 times after the grille anti-wear technology is improved. As shown in the figure, the material flow rate on the surface of the water wall can be completely controlled by properly laying the grid network, and it can be maintained within an ideal range to achieve steady flow effect.

Characteristics of grille anti-wear technology:

1. Novel concept and thorough anti-wear

By optimizing the surface flow field of the water wall, eliminating the local eddy current and the high speed wall flow, the technology realizes effective anti-wear. Technical scheme according to different boiler operation and wear characteristics one furnace one design, the circulating fluidized bed boiler wear symptoms and root. Ensure the boiler to operate in a long period under high load, and increase the fuel adaptability of the boiler (such as increasing the proportion of gangue burning).

2. Long service life of grille

The anti-wear grilles are precision cast by the new rare earth alloy materials developed by our company. They have the characteristics of high temperature wear resistance, high temperature oxidation resistance, high temperature creep resistance and high welding index. Welding can be achieved with strong match, such as the base of 1250 ℃ high temperature is still stable and reliable, and tensile strength of 560 or more mp.

3. Good thermal conductivity

Anti-wear grille plate is metal alloy material, directly welded on the surface of the water wall, with good heat absorption and thermal conductivity, conducive to heat exchange in the furnace.

4. Short construction period and friendly working face

The construction technicians of our company have received professional skills training, and are proficient in the construction technology, so they can complete the construction efficiently (for example, the whole furnace construction of 240T/H boiler only takes 3 days at the soonest). Furnace construction face friendly, no noise and dust pollution in the construction process, can be cross construction, can be combined with the boiler temporary repair, minor repair.

Please feel free to contact me!

Please contact us for more information+86-18062456085